An industrial dryer is a device designed for simultaneously heating and withdrawing moisture from the surface of materials. Industrial dryers have various applications, including pharmaceutical, commercial, and industrial uses. Read More…

Dürr CTS Inc. is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies and drying and curing systems, including industrial dryers and ovens for roll-to-roll processes, web forming processes and conveyor handling of webs, as well as specialized...

At Akona Process Solutions, we are dedicated to engineering advanced industrial dryers that meet the rigorous demands of modern manufacturing and processing industries. We design and build drying systems that deliver precision, consistency, and efficiency, helping our clients achieve optimal production quality and throughput.

At ANDRITZ Separation Inc., we support industries around the world by delivering high-performance drying solutions that optimize efficiency, consistency, and product quality. We design and manufacture advanced dryers engineered to handle everything from fine chemical powders to food ingredients, minerals, and biomass, and we take pride in building systems that perform reliably under the most...

More Industrial Dryer Manufacturers

Industrial dryers are essential components in a wide range of industrial processing applications, where their primary purpose is to efficiently eliminate or remove moisture, water, and other solvents from processed materials. Industrial drying technology is a critical factor in maintaining product quality and meeting regulatory standards, especially in sectors such as food processing, pharmaceuticals, chemicals, plastics, textiles, manufacturing, and minerals processing. Since industrial dryers come in various forms, sizes, and specifications, choosing the right industrial dryer system is vital for optimizing your production process, ensuring product integrity, and maximizing operational efficiency. Careful selection and understanding of industrial drying equipment is necessary to avoid altering or impairing a material's physical, chemical, or biological properties during moisture removal.

The Working Principle of an Industrial Dryer

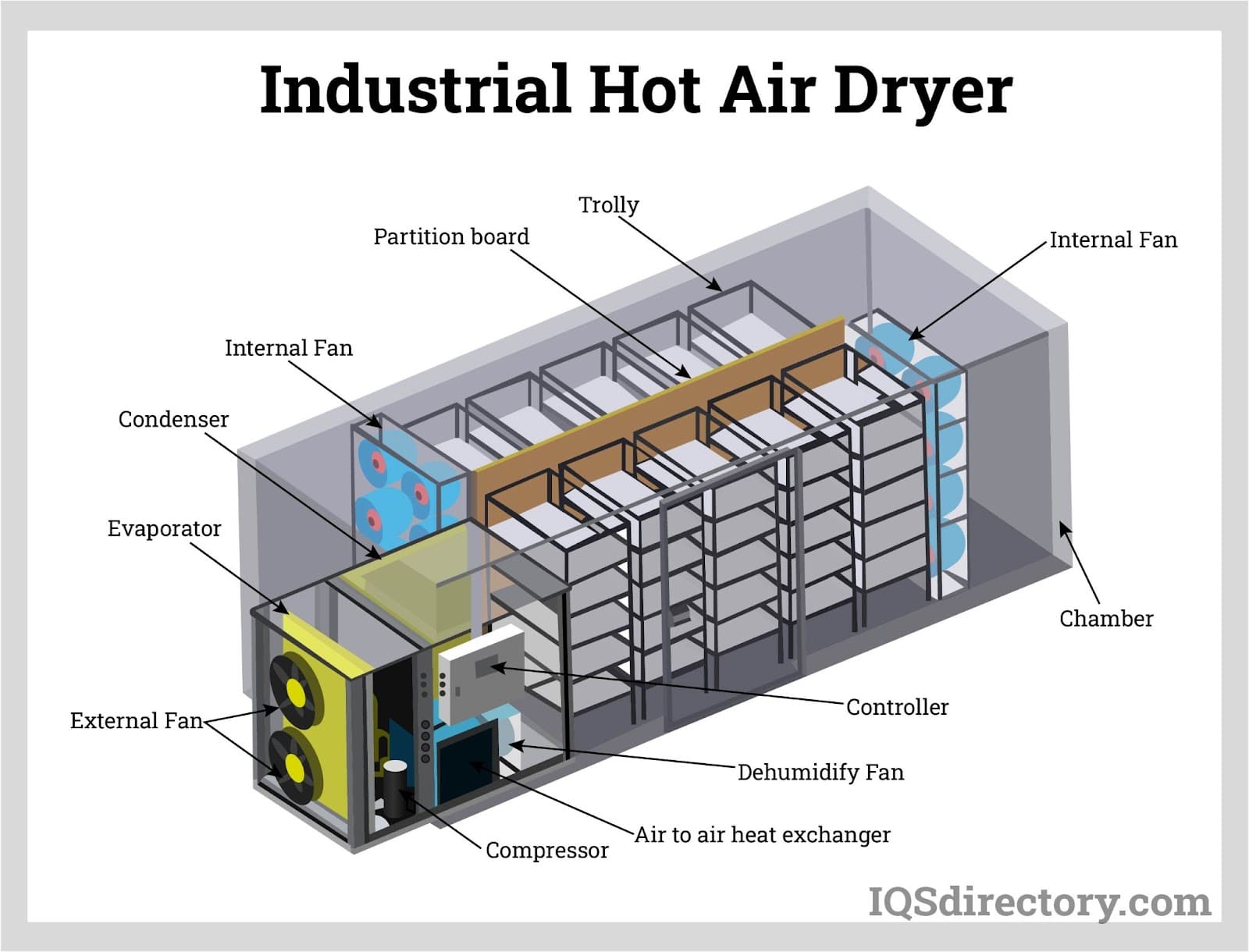

How do industrial dryers work? Industrial dryers operate on advanced drying principles designed to efficiently remove moisture from bulk materials, components, powders, granules, and finished goods. The drying process typically involves a three-stage operation, optimized for either batch drying or continuous drying production. Manufacturers rely on a variety of dryer types to fulfill high-volume and specialized order requirements. Therefore, selecting the best industrial dryer technology for your application is critical—whether you need rapid moisture removal, gentle drying for sensitive products, or scalable throughput.

Step 1: Loading the Product

A sample or product batch is placed inside the industrial dryer chamber. Depending on the configuration, this could involve loading trays, drums, conveyor belts, or fluidized beds with the material to be dried.

Step 2: Controlled Heating and Evaporation

The product is exposed to a controlled heat source—such as hot air, infrared radiation, microwave energy, or vacuum pressure—which raises the temperature of the material. This process draws moisture from the material substrate or surface, transferring it into the surrounding air or vacuum. The material is maintained at a specific temperature and humidity level for a precise time interval, optimized to achieve consistent dryness without degrading sensitive compounds or causing product deformation.

Step 3: Ventilation and Cooling

After the predetermined drying period, the system ventilates heat and evacuates moisture-laden air. The dryer then introduces cooler ambient air to facilitate a gradual cool-down, minimizing the risk of reabsorption and ensuring the product exits the dryer at a stable temperature and desired moisture content.

Types of Heating Methods in Industrial Dryers

Industrial dryers may utilize direct or indirect heating methods. Direct dryers expose products to a flow of heated gases, while indirect dryers transfer heat via conduction or radiation, typically through a heated wall or surface. The choice of heating method depends on product sensitivity, contamination risks, and required throughput.

Whether you are evaluating spray dryers, air dryers, conveyor dryers, or advanced rotary dryers, each dryer design has unique operational characteristics and suitability for specific materials. For instance, stainless steel construction is favored for its durability, hygiene, corrosion resistance, and compliance with food-grade and pharmaceutical standards.

Industrial dryers are available in a range of tank or chamber shapes, including rectangular, cylindrical, and modular designs, often equipped with multiple connections, access doors, sensors, gauges, and programmable controls for process optimization. Some dryers are engineered for batch processing, while others are customized for continuous drying, employing conveyor belts or rotary drums for a steady flow of product. Drying capacities can range from small laboratory-scale units handling a single cubic foot to large-scale industrial dryers that process over 25,000 pounds per hour.

Key Sectors That Rely on Industrial Dryers

Industrial dryers are indispensable in industries such as chemical processing, dairy and food production, fertilizer manufacturing, cereal and grain processing, mineral extraction, paper and pulp, plastics recycling, waste management, and water treatment. Within these sectors, dryers help achieve the required final moisture content, preserve material integrity, and improve shelf life.

Industrial Dryer Construction and Technology

Most industrial dryers are fabricated using robust bolted or welded assemblies, designed to withstand the rigors of high-temperature operation, vacuum, or corrosive media. The selection of drying technique—air drying, freeze drying, spray drying, flash drying, fluid bed drying, or rotary drying—impacts not only drying performance but also energy efficiency, operating costs, and maintenance requirements.

- Air Dryers: These are the most common industrial dryers, directly exposing products to heated air for rapid evaporation of moisture.

- Rotary Dryers: Large drums tumble and agitate materials through hot air for uniform drying, ideal for aggregates, minerals, and bulk solids.

- Fluid Bed Dryers: Steam or heated air is blasted through a perforated plate, suspending particles and creating a fluidized state for even, gentle drying.

- Flash Dryers: Provide a brief, intense burst of heat for immediate moisture removal, often used for heat-sensitive powders or slurries.

- Freeze Dryers (Lyophilizers): Utilize cold temperatures and vacuum to sublimate moisture, preserving biological activity and volatile compounds—commonly used for pharmaceuticals, food, and biotechnology.

- Infrared Dryers: Employ electromagnetic radiation at specific wavelengths for rapid, energy-efficient drying of solid materials with precise control.

- Spray Dryers: Atomize liquids and expose droplets to hot air, causing moisture to evaporate instantly and forming dry powders.

Types of Industrial Dryers and Their Use Cases

Are you looking for the best industrial dryer type for your application? Here’s a comprehensive overview of leading dryer technologies, their core features, and practical use cases.

Conveyor Dryers

Conveyor dryers are engineered for the continuous production and drying of small to medium-sized products. With integrated conveyor belt systems, they enable seamless integration into automated factory processes, supporting high-throughput mass production. Conveyor dryers are highly suitable for industries such as textiles, printed electronics, ceramics, and food processing, where consistent, uniform drying across batches is required. Their modular design allows customization of belt speed, temperature zones, and airflow to accommodate a wide range of materials, including fabrics, coatings, adhesives, and baked goods.

Vacuum Dryers

Vacuum dryers utilize low-pressure environments to lower the boiling point of moisture, enabling gentle drying at reduced temperatures. This technology is particularly advantageous in industries where heat-sensitive products or solvents are present—such as pharmaceuticals, fine chemicals, research laboratories, and electronics manufacturing. Vacuum dryers often feature digital interfaces and programmable controls for real-time monitoring and process automation, minimizing the risk of oxidation and preserving product quality. They are ideal for drying powders, granules, pastes, and specialty chemicals that require contamination-free processing.

Convection Dryers

Convection dryers use heated air to accelerate the dehydration process, providing a gentle and uniform drying environment. These dryers are well-suited for aging, pre-heating, sterilization, baking, thermal storage, and curing operations. Commonly applied in food production, pharmaceuticals, ceramics, and materials manufacturing, convection dryers strike a balance between energy efficiency and product quality, making them a versatile choice for a variety of industrial drying needs.

Rotary Dryers

Rotary dryers are robust and energy-efficient solutions primarily used in heavy industries, such as metal manufacturing, mining, mineral processing, cement production, and aggregate drying. Their rotating drum design ensures thorough mixing and agitation of materials, resulting in rapid and uniform drying with minimal risk of oxidation. Rotary dryers can be integrated with other processes—such as cooling, blending, or calcination—to streamline production and reduce overall operating costs. They are engineered for high-volume, continuous operation and can handle large particle sizes and abrasive materials.

Flotation and Roll-Support Web Dryers

These specialized dryers are designed for web and fabric coating, textile manufacturing, flexible packaging, and paper production. They utilize a combination of stable airflow and precise temperature control to gently dry continuous webs or sheets without physical contact, preventing deformation or surface defects. Flotation dryers are ideal for drying thin films, coated papers, and delicate textiles, ensuring uniform evaporation across the entire web width.

Vertical Tower Dryers

Vertical tower dryers maximize vertical space utilization, making them an excellent choice for facilities with limited floor area. Commonly used in grain handling, seed processing, biomass drying, and food manufacturing, these dryers offer high throughput, energy efficiency, and consistent product quality. By leveraging gravity-assisted material flow, vertical tower dryers reduce handling costs and improve drying uniformity, resulting in lower operational expenses and higher product yields.

Common Applications of Industrial Dryers

Wondering which industries and processes benefit the most from industrial drying solutions? Explore these typical applications to help identify the right dryer for your needs:

Degassing Epoxy Resins

Epoxy resins and other sensitive polymers can actively absorb moisture, leading to poor curing, reduced adhesive strength, or surface defects. Industrial dryers are employed to precondition epoxy materials, ensuring consistent performance even during periods of high humidity. They also play a critical role in degassing—removing trapped air or moisture pockets within resin mixtures to improve mechanical and electrical properties for applications in electronics, aerospace, automotive, and construction.

Electronics Manufacturing

Moisture poses a significant threat to the reliability of electronic components, circuit boards, and assemblies. Industrial dryers are used to dry and heat-treat circuit boards, semiconductors, and microelectronic devices, preventing moisture-induced failures such as delamination, corrosion, and short-circuiting. Drying processes are often integrated into SMT (surface-mount technology) lines, PCB fabrication, and encapsulation stages, ensuring product longevity and performance.

Factory and Production Environments

In addition to product drying, industrial dryers play a vital role in moisture control within conveyor mechanisms, production machinery, and plant infrastructure. By minimizing ambient humidity and preventing moisture accumulation, dryers help extend equipment service life, reduce maintenance costs, and combat gradual mechanical corrosion.

Materials Testing and Quality Assurance

Materials testing laboratories rely on industrial dryers to simulate accelerated aging, evaluate long-term performance, and test the durability of metals, polymers, composites, and coatings under controlled environmental conditions. Dryers enable precise control of temperature and humidity, supporting rigorous quality assurance and product development initiatives.

Pharmaceutical Industry

In the pharmaceutical manufacturing sector, industrial dryers ensure the safe and effective sterilization, incubation, and drying of raw materials, granules, tablets, and medical devices. Compliance with GMP (Good Manufacturing Practices) and stringent regulatory standards demands reliable, validated drying processes to minimize contamination risks and guarantee product efficacy.

Food Processing

Industrial drying is critical in the food industry for preserving fresh ingredients, producing dehydrated foods, drying cereals and grains, and stabilizing dairy products. Dryers used in food processing are designed to maintain nutritional value, color, texture, and flavor while achieving low residual moisture for extended shelf life and food safety.

Chemical and Mineral Processing

Dryers are indispensable in the chemical, fertilizer, and mineral industries for the drying of bulk powders, salts, clays, pigments, and ores. The ability to control temperature profiles and residence times enables the production of free-flowing, homogeneous, and dust-free products that meet strict industry specifications.

Key Benefits and Advantages of Industrial Dryers

Investing in the right industrial dryer system can deliver significant benefits for your operation. Consider these core advantages:

- Faster Processing Times: Industrial dryers significantly reduce drying durations, accelerating production and improving throughput for time-sensitive applications.

- Reduced Product Waste: By delivering consistent, controlled drying, these machines decrease spoilage, minimize rework, and lower associated economic losses.

- Enhanced Profitability: Industrial dryers maximize operational efficiency, reduce labor costs, and support higher production volumes, directly impacting profitability.

- Equipment and Product Protection: In electronics and precision industries, dryers extend the service life of sensitive components by eliminating moisture-related damage.

- Energy-Efficient Designs: Modern industrial dryer models are engineered for optimal energy use, offering features like heat recovery, variable speed drives, and advanced insulation to lower utility expenses.

- Production Line Integration: Flexible configurations allow dryers to fit seamlessly into existing or new manufacturing lines, supporting automated and continuous processes.

- Improved Product Quality: Reliable moisture removal leads to superior product consistency, appearance, shelf stability, and performance.

- Regulatory Compliance: Validated drying processes ensure adherence to industry standards, food safety, and pharmaceutical regulations.

- Customizable Solutions: Industrial dryers can be tailored with precise temperature, humidity, and airflow controls, meeting unique process requirements.

- Scalability: From laboratory-scale R&D to high-capacity industrial operations, dryers are available in sizes and configurations to match any production need.

How to Choose the Right Industrial Dryer: Buying Guide & Decision Factors

Selecting the best industrial dryer manufacturer and system for your facility involves careful consideration of several critical factors. If you’re asking, “What type of industrial dryer is best for my application?” or “How do I compare industrial drying solutions?,” use this checklist to guide your evaluation process:

- Material Characteristics: What are the size, shape, moisture content, heat sensitivity, and flow properties of the material to be dried?

- Production Capacity: What throughput is required—batch or continuous? How many pounds or kilograms must be dried per hour or per cycle?

- Drying Uniformity: Does your application demand consistent moisture profiles throughout the product, or is spot drying acceptable?

- Energy Consumption: What are the long-term operating costs? Are energy-efficient or heat recovery features important for your facility?

- Footprint and Space Constraints: What installation space is available? Do you require vertical or modular designs?

- Process Integration: Does the dryer need to connect with upstream or downstream equipment, such as conveyors, mixers, or packaging lines?

- Control and Automation: What level of process control, monitoring, and data logging do you need for quality assurance and regulatory compliance?

- Contamination and Cleanability: Are there sanitary design requirements for food, pharma, or biotech applications?

- Maintenance and Reliability: What is the expected service life? Are spare parts and technical support readily available?

- Budget and ROI: What is your total cost of ownership, including purchase price, installation, operation, and maintenance?

For the most positive outcome when purchasing an industrial dryer, it’s essential to compare several industrial dryer manufacturers using our curated directory. Each manufacturer profile provides detailed insights into expertise, product range, industry certifications, and technical capabilities. Take advantage of our contact forms to request additional information, technical datasheets, or customized quotes. Our proprietary website previewer allows you to quickly evaluate each supplier’s core competencies. Use our streamlined RFQ form to contact multiple companies simultaneously and gather competitive offers.

Frequently Asked Questions: Industrial Dryers

- What is the difference between batch and continuous industrial dryers?

Batch dryers process a set quantity of material at a time, ideal for specialty or small-scale runs. Continuous dryers handle a steady flow of material for high-volume, automated production. - How do I calculate the required drying capacity?

Drying capacity depends on initial/final moisture content, material throughput, and required drying time. Consult with manufacturers for engineering calculations tailored to your process. - Which dryer type is best for heat-sensitive materials?

Vacuum, freeze, or infrared dryers minimize thermal degradation and are optimal for pharmaceuticals, food, or specialty chemicals. - How can I maximize energy efficiency in my drying operation?

Look for dryers with heat recovery systems, variable frequency drives, and advanced insulation. Regular maintenance and process optimization also reduce energy use. - What certifications should I look for in an industrial dryer?

Key certifications include ISO 9001, CE, ATEX (for explosive environments), FDA or GMP compliance (for food/pharma), and UL or CSA (for electrical safety).

Ready to Find the Ideal Industrial Dryer?

If you’re ready to request a quote or need expert guidance on selecting the right industrial dryer, contact our team or browse our directory of industrial dryer manufacturers. Whether you need a solution for food processing, chemical drying, pharmaceuticals, electronics, or materials testing, we’re here to help you compare options, evaluate features, and make an informed purchasing decision.

Explore these prompts to guide your search:

- What is the best industrial dryer for sensitive food ingredients?

- Which drying technology offers the lowest energy consumption?

- How do I ensure GMP compliance in pharmaceutical drying?

- What features should I prioritize for high-throughput applications?

- How do I compare rotary vs. fluid bed dryers?

- What are the maintenance requirements for industrial dryers?

Visit our learning center for more in-depth articles, buying guides, and case studies on industrial dryers, drying technology, and process optimization.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services